New report reveals how logic-driven design cuts rework by 60% and powers the next generation of smart, agile manufacturing.

Parametric modeling is the backbone of agility. We build logic, not just geometry.”

— Kuldeep Gajjar, Director, Tesla Mechanical Designs

CA, UNITED STATES, November 21, 2025 /EINPresswire.com/ -- In the rapidly evolving world of global manufacturing, design agility is no longer optional; it is the basis of competitive advantage. As industries move toward higher customization, faster iteration cycles, and digitally integrated production

environments, engineering teams require modeling methodologies that deliver precision, flexibility, and repeatability. Tesla Mechanical Designs, a leading provider of high-quality CAD, engineering, and mechanical design services, has released new insights confirming a significant shift across manufacturing: parametric modeling is dramatically reducing rework, improving collaboration, and accelerating product development for companies of every size.For more than a decade, Tesla Mechanical Designs has been at the forefront of advanced engineering design methodologies. Their latest report explores how parametric modeling, often contrasted with direct modeling, has emerged as the superior approach for complex product development in industries ranging from automotive to aerospace, industrial equipment, consumer appliances, and specialty machinery.

𝗧𝗵𝗲 𝗘𝘃𝗼𝗹𝘂𝘁𝗶𝗼𝗻 𝗳𝗿𝗼𝗺 𝗗𝗶𝗿𝗲𝗰𝘁 𝗠𝗼𝗱𝗲𝗹𝗶𝗻𝗴 𝘁𝗼 𝗣𝗮𝗿𝗮𝗺𝗲𝘁𝗿𝗶𝗰 𝗜𝗻𝘁𝗲𝗹𝗹𝗶𝗴𝗲𝗻𝗰𝗲

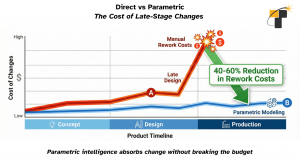

Traditional direct modeling tools have long been praised for their simplicity. Engineers can push, pull, and manipulate geometry quickly, making direct modeling appealing during conceptual phases. However, as products become more intricate and multi-disciplinary, direct modeling often exposes limitations: lack of dependency control, difficulty in driving complex variations, and high rework when design changes occur late in the process.

Parametric modeling, by contrast, organizes design intelligence into structured relationships. Dimensions, constraints, parameters, and feature histories form a dynamic system in which change propagates automatically. As Tesla Mechanical Designs highlights, this is exactly the capability modern manufacturers require.

“Parametric modeling eliminates guesswork and minimizes manual intervention when modifications arise,” the technical team at Tesla Mechanical Designs explains. “Most rework happens because a single design update forces teams to rebuild downstream elements. Parametric modeling prevents that by establishing relationships that update consistently and accurately, even under significant redesign.”

The company's latest findings indicate that for products with evolving specifications, direct modeling often leads to design fragmentation, inconsistencies between assemblies, and bottlenecks during production preparation. Parametric modeling, however, enables agility without compromising structural integrity or manufacturing precision.

𝗧𝗵𝗲 𝗖𝗼𝘀𝘁 𝗼𝗳 𝗥𝗲𝘄𝗼𝗿𝗸: 𝗪𝗵𝘆 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗲𝗿𝘀 𝗖𝗮𝗻 𝗡𝗼 𝗟𝗼𝗻𝗴𝗲𝗿 𝗜𝗴𝗻𝗼𝗿𝗲 𝗜𝘁

Rework has always been a costly aspect of engineering. However, its impact on today’s supply chains has grown significantly due to:

✔️ Compressed delivery cycles

✔️ Increased customization

✔️ Complex multi-vendor collaboration

✔️ Rapidly shifting market demands

✔️ Higher demand for digital twins and simulation-ready models

Tesla Mechanical Designs reports that parametric modeling can reduce rework by up to 40–60% in full product-development cycles, particularly in scenarios involving repeated revisions. According to their engineering leads, the root cause of excessive rework is often the lack of structured design logic.

“Revisions are inevitable,” the team notes. “But rebuilding an assembly or manually aligning features every time a dimension changes is not. Manufacturers are now beginning to view design intelligence, not just design geometry, as the key to efficiency.”

With parametric value embedded into each feature, an engineer can modify a core dimension, such as diameter, thickness, or assembly spacing, and watch the entire model adapt accordingly. This reduces the likelihood of error, speeds up approval cycles, and ensures seamless integration with simulation, CAM, and PLM systems.

𝐖𝐡𝐲 𝐌𝐨𝐝𝐞𝐫𝐧 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐅𝐚𝐯𝐨𝐫𝐬 𝐏𝐚𝐫𝐚𝐦𝐞𝐭𝐫𝐢𝐜 𝐌𝐨𝐝𝐞𝐥𝐢𝐧𝐠

Tesla Mechanical Designs’ new report highlights several reasons why manufacturers are rapidly transitioning to parametric systems:

✔️ 𝗗𝗲𝘀𝗶𝗴𝗻 𝗜𝗻𝘁𝗲𝗻𝘁 𝗶𝘀 𝗣𝗿𝗼𝘁𝗲𝗰𝘁𝗲𝗱: Parametric modeling preserves the original engineering logic. Every design element, holes, fillets, ribs, cutouts, or patterns, is linked through controlled rules. When change is required, modifications align with original reinforcement strategies and functional requirements.

✔️ 𝗦𝗰𝗮𝗹𝗮𝗯𝗹𝗲 𝗳𝗼𝗿 𝗠𝘂𝗹𝘁𝗶-𝗩𝗮𝗿𝗶𝗮𝗻𝘁 𝗣𝗿𝗼𝗱𝘂𝗰𝘁𝗶𝗼𝗻: Manufacturers across industries now produce multiple variants of a product. Parametric models allow teams to create families of parts, enabling mass customization with minimal redesign effort.

✔️ 𝗦𝘂𝗽𝗲𝗿𝗶𝗼𝗿 𝗖𝗼𝗹𝗹𝗮𝗯𝗼𝗿𝗮𝘁𝗶𝗼𝗻 𝗔𝗰𝗿𝗼𝘀𝘀 𝗚𝗹𝗼𝗯𝗮𝗹 𝗧𝗲𝗮𝗺𝘀: Digital collaboration has become standard across multi-location engineering teams. Parametric models reduce confusion because every feature carries meaning. When one expert makes a change, others understand the intent instantly.

✔️ 𝗗𝗶𝘀𝗰𝗼𝘃𝗲𝗿𝘆 𝗼𝗳 𝗗𝗲𝘀𝗶𝗴𝗻 𝗙𝗹𝗮𝘄𝘀 𝗘𝗮𝗿𝗹𝘆 𝗶𝗻 𝘁𝗵𝗲 𝗖𝘆𝗰𝗹𝗲: Parametric relationships make it easier to stress-test variations, run simulations, and ensure manufacturability. Tesla Mechanical Designs emphasizes that early detection reduces expensive late-stage revisions.

✔️ 𝗜𝗻𝘁𝗲𝗴𝗿𝗮𝘁𝗶𝗼𝗻 𝘄𝗶𝘁𝗵 𝗦𝗺𝗮𝗿𝘁 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴: Modern manufacturing relies heavily on automation, digital twins, CNC programming, and robotics. Parametric models integrate seamlessly with advanced toolpaths, tolerance stackups, and simulation workflows, enabling an uninterrupted digital thread.

𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻𝘀: 𝗔 𝗗𝗲𝗰𝗮𝗱𝗲 𝗼𝗳 𝗣𝗮𝗿𝗮𝗺𝗲𝘁𝗿𝗶𝗰-𝗗𝗿𝗶𝘃𝗲𝗻 𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻

Based in India and serving clients globally, Tesla Mechanical Designs has established itself as a trusted partner for manufacturers seeking precision CAD modeling, assembly engineering, parametric optimization, design automation, BIM-to-CAD transitions, sheet metal modeling, and product development support.

The design teams specialize in all major parametric modeling platforms, including SOLIDWORKS, AutoCAD, Inventor, CATIA, Creo, NX, and Fusion 360. This expertise allows them to build highly intelligent models tailored to the needs of various industries.

“We are not just drafting geometry; we are engineering futures,” says the leadership team. “Product design today is a living process. Manufacturers require models that evolve, models that carry intent, intelligence, and repeatable logic. Parametric modeling is the backbone of that evolution.”

No comments:

Post a Comment